-

Fluid Injection & Pressure Testing

50L Fluid Injection System

Standalone spring loaded 16/28/50 liter reservoir to be used for filling and injection of fluid or chemicals subsea.

A complete system consisting of a spring loaded subsea reservoir, ROV isolations valve, hose kit and stab can be used as an add-on to the ROV for filling and injection applications. Hydraulic driven motor-pump can be added to the system to increase level of flow and pressure. Standard setup comes with 16L reservoir, 3 meter hose kit and a ROV Isolation Valve.

-

Fluid Injection & Pressure Testing

Hydraulic Power Unit

IHPU is designed to be a compact and highly effective tool for subsea pressure testing from ROV.

The IHPU comes with integrated dual acting booster pump, remote controlled proportional flow control valves and pressure reducing valves for maximum pump control. A pressure safety valve are installed on HP output line to avoid over-pressurization on 3rd part equipment.

The IHPU have an in-built digital flowmeter and pressure sensor for reading of accurate flow and pressure consumption. -

Fluid Injection & Pressure Testing

IHPU 10kpsi 690 Bar

The 10,000psi IHPU is a versatile tool that can be used for numerous subsea applications including; Operating BOP Tooling, Transferring Media and Pressure Testing.

The output pressure is directly proportional to the output pressure. This allows the output to be adjusted from 0 – 10,000 psi. The pump can be connected to any subsea reservoir by the suction port (12 JIC). We can supply various sizes of soft reservoir and piston reservoir with an electronic readout depending on requirements.

-

Fluid Injection & Pressure Testing

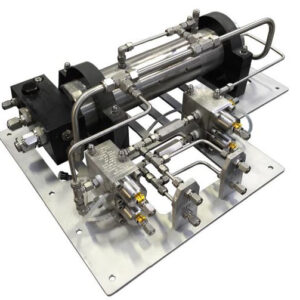

Pressure Test Unit (PTU)

Pressure Test Unit (PTU) is designed to be a compact and highly effective tool for subsea pressure testing from ROV.

The PTU comes with integrated dual acting booster pump, Flow Control Valve and two Pressure Reducing Relieving Valves on inlet supply for tuning- and maximum pump pressure control. PTU can be setup for low pressure test through separate LP or high pressure tests though HP circuits. Each system have separate Safety Pressure Valves on pressure outlet line. Digital sensor and logging software gives live pressure feedback and recording options for pressure test certificates.

-

Fluid Injection & Pressure Testing

Subsea Accumulator System

In relation to drilling standard API 53S the Accumulator System has been designed and tested to close BOP critical functions within 45 seconds timeframe.

The Accumulator System is a standalone basket equipped with 15 off 54L 5,000 PSI bottles, subsea displays and battery driven control system for pressure and flow monitoring and logging. A ROV friendly valve control panel will allow ease operation of the system and can be operated by all types of ROV’s with manipulator arm. Accumulators can be recharged subsea through stab and receptacle system.

-

Fluid Injection & Pressure Testing

Subsea Pressure Logger

Subsea Pressure Logger (SPL) is a compact tool which allows the ROV to perform pressure tests on subsea equipment, typically back seal testing.

The Subsea Pressure Logger consist of a ROV operated isolation valve, pressure gauge and a digital pressure sensor showing live pressure feedback in surface software. The software have recording and print of pressure test certificates with graph. The small footprint will allow for ease interface on a ROV or belly skid.

-

Fluid Injection & Pressure Testing

Subsea Pump Unit

The Subsea Pump Unit is a standalone pump basket with high fluid volume capacity for injection and flushing applications. The pump is powered by an standard WROV and can either supply mineral based oil, water glycol based fluids and MEG.

The SPU will increase efficiency of fluid injection and flushing performed from e.g. IMR vessels by removing traditional cost-driven deck spread such as HPU, pumps, reel and downline. The basket comes with a 1100 litres flexible tank, hydraulic driven motor-pump unit for 5,000 PSI pressure and a ROV control panel.

-

Fluid Injection & Pressure Testing

Subsea Reservoir 2200L

Subsea Reservoir Pump Basket is designed to reduce cost and HSE impact during pumping and injection operations by removing surface equipment from vessel deck.

The Reservoir Basket have 2 off 1100L fluid tanks that can be filled with two types of fluid prior to deployment. Hydraulic driven transfer pump are operated by an ROV, connected with a jumper hose, hotstab and receptacle. The large reservoir is ideally suited for any deep water applications to save time in operations requiring large volume of fluid.